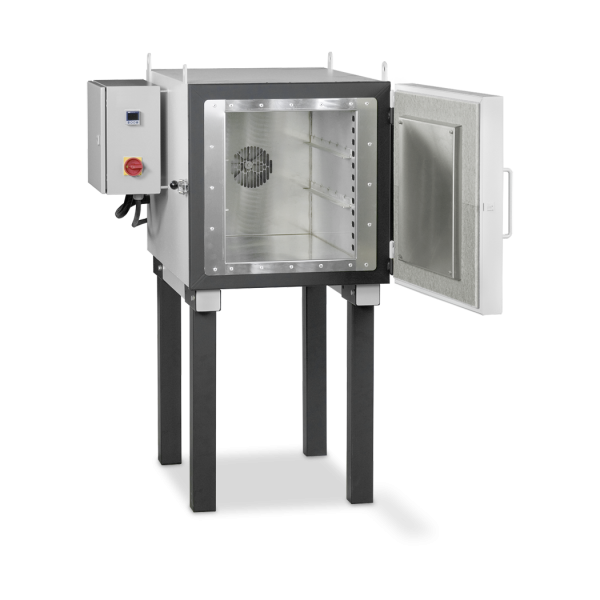

Chamber Furnace KU 70/45

- Volume 70 litres

- Int. dimensions (w x d x h) 350 x 500 x 400 mm

- Power 4 kW

The KU 70/45 Air Circulating Furnace from the KU series has a volume of 70 litres and is suitable for temperatures up to 450°C.

This model is suitable for a variety of materials and applications and is used for tempering, aging, preheating, drying, shrinking, curing and testing for instance. The versatile furnaces can be used for many other materials and applications such as bending, hardening or aging of plastics.

The robust housing construction consists of high-quality steel sheets. The internal housing is made of heat-resistant stainless steel guaranteeing a long service life and is extremely durable and corrosion-resistant. The high-quality insulation ensures efficient use of energy and contributes to reduced electricity costs and low external temperatures.

- 1-side heating with powerful air circulation

- Tubular heating elements

- 2-layer insulation structure (80mm)

- High temperature accuracy

One of the principal characteristics of this series is the even distribution of temperature, achieved through heating from several sides and powerful air circulation. These furnaces can be equipped with inserting shelves and two fitted inserting trays to allow the best utilisation of the interior.

Overview

- Product group

- Kiln

- Design

- Chamber Furnace

- Type

- KU series

- Tmax

- 450°C

Energy

- Energy type

- Electrical

- Power

- 4 kW

- Supply

- 10,8 A

- Voltage

- 3/N/PE 400V AC

- Connection

- CEE 16 A

Dimensions

- Volume

- 70 litres

- Int. dimensions (w x d x h)

- 350 x 500 x 400 mm

- Ext. dimensions (W x D x H)

- 695 x 1125 x 1400 mm

- Weight

- 220 kg

Equipment

- Insulation

- 2-layer, 80 mm

- Heating

- 1-side

- Heating elements

- Tubular heating elements

- Control

- Jumo dTron

Torsion-resistant welded steel housing

The housing consists of a torsion-resistant welded construction. Each furnace is manufactured by hand and leaves the factory after undergoing extensive quality controls.

Durable textured paint finish

The high-quality light-grey RAL 7035 textured coating protects the furnace body and steel construction.

Air circulation allows for high temperature uniformity

ROHDE-designed air circulating fans are decoupled from the drive motor and are quiet, durable and above all easy to service.

Excellent temperature uniformity of +/- 5 K

Excellent temperature uniformity of +/- 5 K (according to DIN 17052) is achieved in the useful space by using powerful air circulation in the furnace interior.

Robust swing door allows for safe opening

The convenient operation of the swing door allows easy opening of the furnace. The solid door handle ensures smooth operating procedures even when opening the hot furnace while the process is running.

Flexible door sealing allows for thorough door closing

A flexible insulating cord ensures a seal between the door and the furnace opening. Minor unevenness can be corrected and the door can be closed flush with the furnace.

Efficient 2-layer insulation structure

A sophisticated 2-layer insulation structure allows for required temperatures to be achieved using less energy. The insulation consists of two layers of fibers with 40 and 40mm thickness and thus achieves high energy efficiency even in continuous use.

Easy-to-maintain switchgear mounted in a Rittal switch cabinet

The switchgear is mounted in a Rittal switch cabinet and can be easily maintained and accessed.

Low-wear contactors for control

The furnace is controlled by low-wear, durable contactors.

Precise temperature measurement with “Type K” thermocouple

The installed NiCrNi thermocouple (type K) is protected against damage and guarantees exact temperature measurement at all times.

The “CEE 32 A” connector allows for easy connection

The standardised CEE 32 A connector allows for easy connection and quick and safe start-up.

Components from well-known manufacturers contribute to long service life

We only obtain our electric components from well-known manufacturers (e.g. SIEMENS, MOELLER, WEIDMÜLLER, RITTAL).

Furnace construction in accordance with DIN EN 746-1

The unit is constructed and manufactured in accordance with DIN EN 746-1 Industrial Thermoprocessing Equipment.

Switchgear design in accordance with DIN EN 60519

The switchgear is designed in accordance with DIN EN 60519 Safety in Installations for Electroheating.

2-year warranty despite intense use

We deliberately refuse to reduce the warranty period despite commercial furnaces being used intensely except parts that are subject to wear.